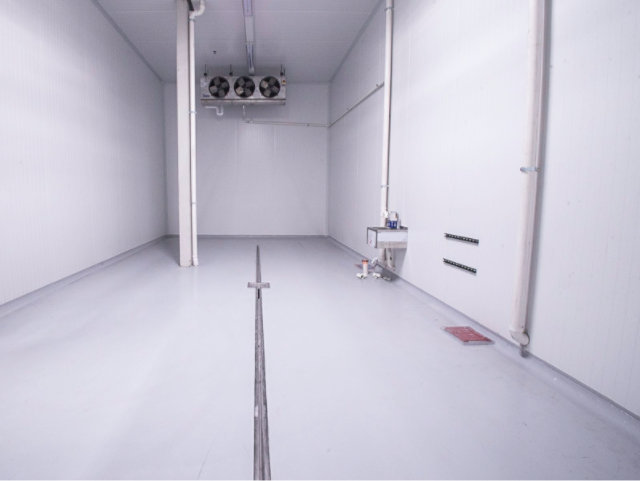

Best Cool Room Flooring options

Ideal Coolroom Flooring by Diamond Grind

Ensuring the optimal functionality of your cold storage facility is crucial. Any issues can lead to significant losses of valuable produce. Installing a reliable coolroom flooring system is vital to maintaining seamless operations.

When selecting coolroom flooring for a commercial space, polyurethane cement floors are the superior choice. These floors offer excellent flexibility and impact resistance, outperforming epoxy floors in environments subject to constant temperature fluctuations.

Polyurethane concrete floors are also highly resistant to chemicals and extreme temperatures, preventing cracks and delamination. This durability and adaptability make polyurethane cement coolroom floors the ideal solution for commercial coolrooms.

Comprehensive Coolroom Flooring Inspections

At Diamond Grind, we understand that no two businesses are the same. That’s why we like to conduct thorough inspections of the premises as part of our quoting process. We begin with understanding your specific needs through questions like:

– What’s the foot traffic like in your coolroom?

– Do you work with hazardous chemicals?

– What is the required temperature range in the room?

– How frequently is the room cleaned?

– Is the concrete flooring stable?

These insights allow us to recommend the best flooring solution for your unique environment, ensuring that we explore all the options for your job together.

Preparing Coolroom Floors for Coating

Once we’ve assessed your coolroom, we address any existing issues with the concrete. Uneven or rough concrete can jeopardise the integrity of your new flooring.

Our team prepares the floor by applying special underlayment toppings to achieve a perfectly flat surface. We also use vacuum grinders and shot blasting to remove any remnants of old coatings, ensuring a pristine surface ready for the new layer.

During our initial inspection, we determine the necessary under-layering and provide an accurate timeline for the project, helping you efficiently plan for any required downtime.

Customisable Coolroom Flooring Design

Unlike polished concrete floors, epoxy and polyurethane cement floors offer extensive customisation options. You can choose from various colours to match your room’s aesthetic. Popular choices like white, beige, and grey highlight spills quickly.

For added safety, we can incorporate anti-slip epoxy coatings. If your operations require high floor grip, we can apply a special matte coating that maintains ease of cleaning.

Benefits of Epoxy and Polyurethane Flooring

Choosing Diamond Grind’s resin flooring for your coolroom provides numerous advantages:

Ease of Cleaning: Smooth, resin floors allow for quick and efficient cleaning, directing debris toward the drain with minimal effort.

Chemical Resistance: Our floors withstand industrial-grade solvents and cleaning agents without damage, ensuring a sterile environment.

Quick Curing Time: Our flooring systems are applied within a day, with a curing time of just 2-8 hours, ensuring minimal downtime and maximum efficiency.

Temperature Resistance: Our floors remain stable and safe even at sub-zero temperatures, preventing leaks and cracks.

Cost-Effective: A professional installation from Diamond Grind ensures long-term durability, providing you with peace of mind and saving you money on repairs and replacements.

✅ Let's Talk — DiamondGrind

100% free consultation — no commitment required.