Polyurethane Cement Flooring.

Polyurethane Cement Flooring: The Ultimate Solution for Demanding Environments

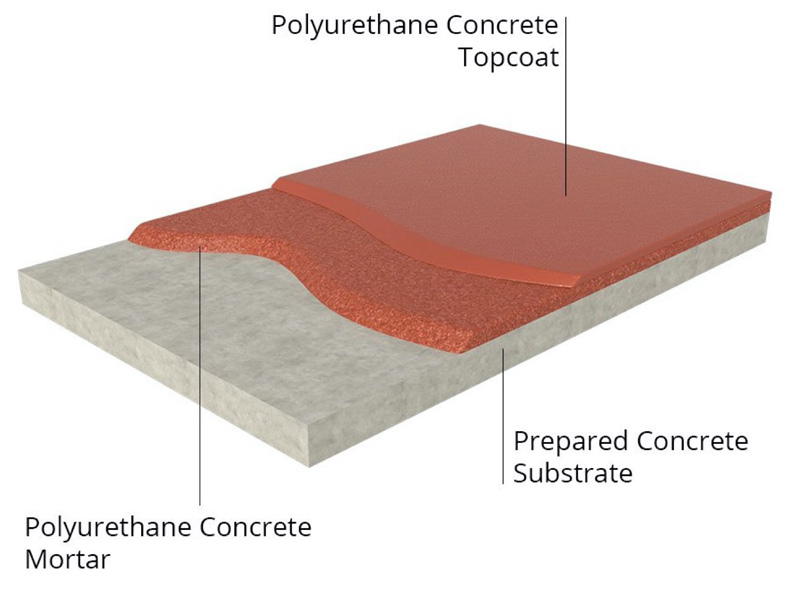

Polyurethane cement floors, also known as urethane cement floors or polyurethane concrete floors, offer a specialised concrete surface solution with exceptional durability and hygiene. Combining the inherent strength of traditional concrete with the flexibility and chemical resistance of polyurethane, this flooring type is ideal for a wide range of commercial and industrial applications.

Often referred to as urethane cement or polyurethane concrete, these floors excel in demanding environments, particularly within the food and beverage industry, thanks to their toughness, hygienic properties, resistance to chemicals and thermal shock, slip-resistant qualities, and design flexibility.

Key Benefits of Polyurethane Cement Flooring

-

Hygienic Surface:

The seamless and non-porous nature of polyurethane makes it easy to clean and sanitise, crucial for preventing contamination in food processing facilities.

-

Chemical Resistance:

Highly resistant to cleaning agents, acids, alkalis, and oils, making it ideal for environments where chemical spills are common.

-

Durability:

Withstands heavy foot traffic, machinery, and equipment without cracking or chipping. Also resistant to abrasion and impact.

-

Thermal Stability:

Urethane cement can endure extreme hot and cold temperatures, essential for facilities with freezers or large temperature variations.

-

Slip Resistance:

Provides a safe working environment, even when wet, reducing the risk of slips and falls.

-

Customisable Aesthetics:

Available in various colours and finishes to match your facility’s design requirements. Explore colour choices

-

Toughness:

The polyurethane mix creates a tough, abrasion-resistant surface, ideal for high-traffic areas like factories and commercial kitchens.

-

Cleanliness and Sanitation:

Easy to sweep, mop, and sanitise, preventing the trapping of dirt and debris.

-

Long Lifespan:

With proper care, polyurethane cement floors offer a cost-effective, long-lasting flooring solution.

-

Ease of Installation:

Relatively quick and easy to install, minimising downtime for your operations.

-

Environmental Benefits:

Made from sustainable materials with a low environmental impact. Their long lifespan reduces waste.

-

Temperature Regulation:

Insulating properties help maintain consistent temperatures, crucial for food storage and processing.

-

Noise Reduction:

The dense composition reduces noise levels, creating a more comfortable working environment.

-

Compliance with Industry Standards:

Meets stringent health and safety regulations for the food and beverage industry.

Epoxy or Polyurethane cement?

The differences between epoxy and polyurethane cement floors are their chemical makeup and their physical properties.

Epoxy is a thermosetting resin which hardens when exposed to heat or a catalyst. Epoxy floors are known for their hardness, durability, and chemical resistance, making them popular for industrial and commercial applications.

On the other hand, polyurethane is a thermoplastic polymer and, when integrated with cement creates floors known for their flexibility, impact resistance, temperature resilience and ability to withstand heavy loads and foot traffic.

Ultimately, the choice between epoxy and polyurethane cement flooring depends on the application’s specific needs, including the type of industry, the amount of traffic, the types of chemicals and substances present, and the level of flexibility and impact resistance required. For more information about benefits, see this article.

We at Diamond Grind are happy to discuss the differences in detail and help you make the best choice for your particular purposes.

Let’s Chat – No Strings Attached!

Please call Diamond Grind on

1800 587 172.

Read more about Polyurethane Cement Flooring from our Blog.

Best concrete dairy flooring

This in-depth guide explores the benefits of PUC, including its slip resistance, durability, hygiene advantages, and ease of maintenance. Learn how upgrading from traditional concrete to polyurethane cement can improve safety for both farmers and livestock, reduce long-term costs, and meet Australian industry standards. Whether you’re renovating an existing dairy or building a new one, this article will help you make an informed decision about your dairy floor investment.

Which is better epoxy or polyurethane cement?

Discover the key differences between epoxy and polyurethane cement coatings for industrial and commercial flooring. Learn about their durability, chemical resistance, aesthetics, and cost to choose the best solution for your facility.

Commercial Industrial Flooring

Choosing the right flooring for your commercial or industrial facility is crucial. Learn about the benefits of polyurethane cement, epoxy, and polished concrete flooring. This article covers everything from durability and chemical resistance to cost-effectiveness and maintenance. Read on to make an informed decision for your business..

✅ Let's Talk — DiamondGrind

100% free consultation — no commitment required.