Polyurethane Cement Flooring.

Polyurethane Cement Flooring: The Ultimate Solution for Demanding Environments

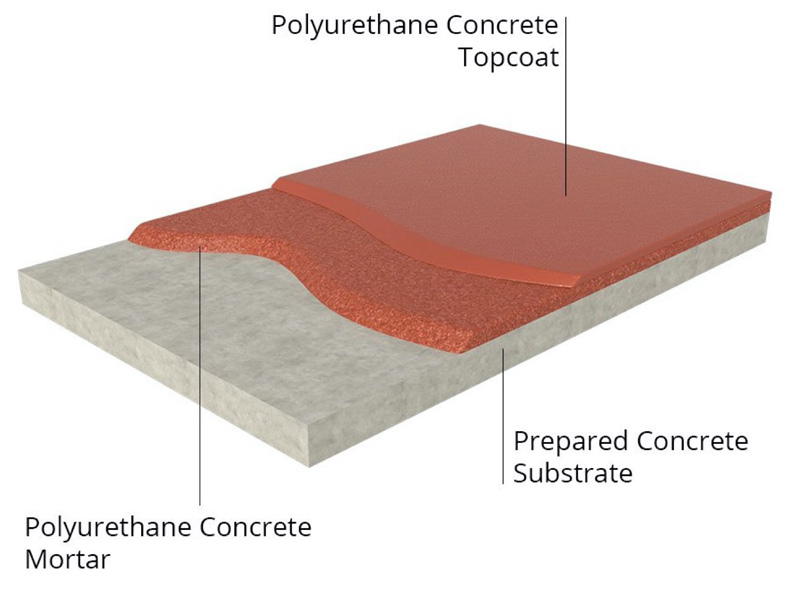

Polyurethane cement floors, also known as urethane cement floors or polyurethane concrete floors, offer a specialised concrete surface solution with exceptional durability and hygiene. Combining the inherent strength of traditional concrete with the flexibility and chemical resistance of polyurethane, this flooring type is ideal for a wide range of commercial and industrial applications.

Often referred to as urethane cement or polyurethane concrete, these floors excel in demanding environments, particularly within the food and beverage industry, thanks to their toughness, hygienic properties, resistance to chemicals and thermal shock, slip-resistant qualities, and design flexibility.

Key Benefits of Polyurethane Cement Flooring

-

Hygienic Surface:

The seamless and non-porous nature of polyurethane makes it easy to clean and sanitise, crucial for preventing contamination in food processing facilities.

-

Chemical Resistance:

Highly resistant to cleaning agents, acids, alkalis, and oils, making it ideal for environments where chemical spills are common.

-

Durability:

Withstands heavy foot traffic, machinery, and equipment without cracking or chipping. Also resistant to abrasion and impact.

-

Thermal Stability:

Urethane cement can endure extreme hot and cold temperatures, essential for facilities with freezers or large temperature variations.

-

Slip Resistance:

Provides a safe working environment, even when wet, reducing the risk of slips and falls.

-

Customisable Aesthetics:

Available in various colours and finishes to match your facility’s design requirements. Explore colour choices

-

Toughness:

The polyurethane mix creates a tough, abrasion-resistant surface, ideal for high-traffic areas like factories and commercial kitchens.

-

Cleanliness and Sanitation:

Easy to sweep, mop, and sanitise, preventing the trapping of dirt and debris.

-

Long Lifespan:

With proper care, polyurethane cement floors offer a cost-effective, long-lasting flooring solution.

-

Ease of Installation:

Relatively quick and easy to install, minimising downtime for your operations.

-

Environmental Benefits:

Made from sustainable materials with a low environmental impact. Their long lifespan reduces waste.

-

Temperature Regulation:

Insulating properties help maintain consistent temperatures, crucial for food storage and processing.

-

Noise Reduction:

The dense composition reduces noise levels, creating a more comfortable working environment.

-

Compliance with Industry Standards:

Meets stringent health and safety regulations for the food and beverage industry.

Epoxy or Polyurethane cement?

The differences between epoxy and polyurethane cement floors are their chemical makeup and their physical properties.

Epoxy is a thermosetting resin which hardens when exposed to heat or a catalyst. Epoxy floors are known for their hardness, durability, and chemical resistance, making them popular for industrial and commercial applications.

On the other hand, polyurethane is a thermoplastic polymer and, when integrated with cement creates floors known for their flexibility, impact resistance, temperature resilience and ability to withstand heavy loads and foot traffic.

Ultimately, the choice between epoxy and polyurethane cement flooring depends on the application’s specific needs, including the type of industry, the amount of traffic, the types of chemicals and substances present, and the level of flexibility and impact resistance required. For more information about benefits, see this article.

We at Diamond Grind are happy to discuss the differences in detail and help you make the best choice for your particular purposes.

Read more about Polyurethane Cement Flooring from our Blog.

Best concrete dairy flooring

Cracked, slippery concrete isn’t just a headache, it’s a risk to your herd and your bottom line. From lactic acid erosion to livestock injuries, the wrong surface can be a major liability. We’ve made this comprehensive guide on why Polyurethane Cement is the future of NSW dairy flooring. Learn how to:

Achieve a 48-hour return-to-service.

Meet AS 2622-2021 slip-resistance standards.

Reduce washdown time by 30%.

Protect your investment and your animals.

Check out our expert tips for local farmers:

DiamondCrete – Food and Beverage flooring

Is your facility floor a secret liability? In the high-pressure world of food production, your flooring needs to be more than just a surface—it needs to be a hygiene hero. From scorching kitchens to sub-zero cold rooms, DiamondCrete PU Cement offers the best flooring for the food and beverage industry. Discover how this chemical resistant and sustainable flooring solution protects your staff, ensures 100% hygiene compliance, and withstands the toughest industrial conditions.

Epoxy Coats vs Paints : Mastering the Art of Flooring

Are you confused between epoxy coatings and epoxy paints? This article unravels the distinctions, helping you make an informed decision. Learn about each option’s components, installation, price considerations, and maintenance. Discover why epoxy coatings are often the preferred choice for durability and long-term investment in residential and commercial spaces.

FAQ,s

What is polyurethane cement flooring and why choose it for my facility?

Polyurethane cement flooring, also known as urethane cement or polyurethane concrete, combines the strength of concrete with the flexibility and chemical resistance of polyurethane. It’s ideal for demanding environments needing durability, hygiene, and thermal shock resistance. Choose it for its seamless, non-porous surface that prevents contamination and withstands heavy traffic. For more on how it compares to other options, visit our Epoxy Flooring page.

What are the key benefits of polyurethane cement floors?

Key benefits include superior hygiene for easy sanitisation, high chemical resistance to acids and oils, exceptional durability against abrasion and impact, thermal stability for extreme temperatures, and slip resistance for safety. It also offers a long lifespan, reducing long-term costs, quick installation to minimise downtime, and compliance with standards like HACCP. These make it a cost-effective choice for high-traffic areas in NSW.

Which industries or applications suit polyurethane cement flooring best?

It’s perfect for food and beverage sectors like dairies, wineries, and commercial kitchens, as well as factories, garages, workshops, and areas with chemical exposure or temperature variations. Its hygienic, anti-slip properties ensure safety and compliance in facilities across Sydney, Hunter Valley, and regional NSW. If you’re in the food industry, explore our DiamondCrete page for tailored HACCP-compliant solutions.

How does polyurethane cement flooring compare to epoxy flooring?

Polyurethane cement offers greater flexibility, impact resistance, and thermal resilience, making it better for heavy loads and temperature fluctuations, while epoxy provides hardness and chemical resistance for less demanding settings. The best choice depends on your needs—polyurethane excels in food processing due to its thermoplastic properties. For a detailed comparison, check our blog post on Which is Better: Epoxy or Polyurethane Cement?.

How can I get a quote for polyurethane cement flooring in NSW?

Call us at 1800 587 172 for a 100% free, no-obligation consultation and quote. We’re based on the NSW Central Coast and serve areas like Sydney, Hunter Valley, and beyond. Let’s discuss your project today!

100% free consultation — no commitment required.