What is MMA Floor Covering? A Comprehensive Guide.

In the world of industrial and commercial flooring, choosing the right system is crucial for durability, safety, and efficiency—especially in demanding environments like Sydney’s breweries, warehouses, or food processing facilities. At Diamond Grind, we often recommend options like polyurethane cement or epoxy for their robustness, but another standout choice is MMA floor covering (Methyl Methacrylate). This fast-curing resin system is gaining popularity in NSW for its rapid installation and extreme resilience. Drawing from our 20+ years of experience and insights from industry sources, this guide explores what MMA flooring is, its benefits, applications, and how it compares to alternatives. Whether you’re renovating a high-risk spill area or seeking minimal downtime, MMA could be the solution.

Understanding MMA Floor Covering

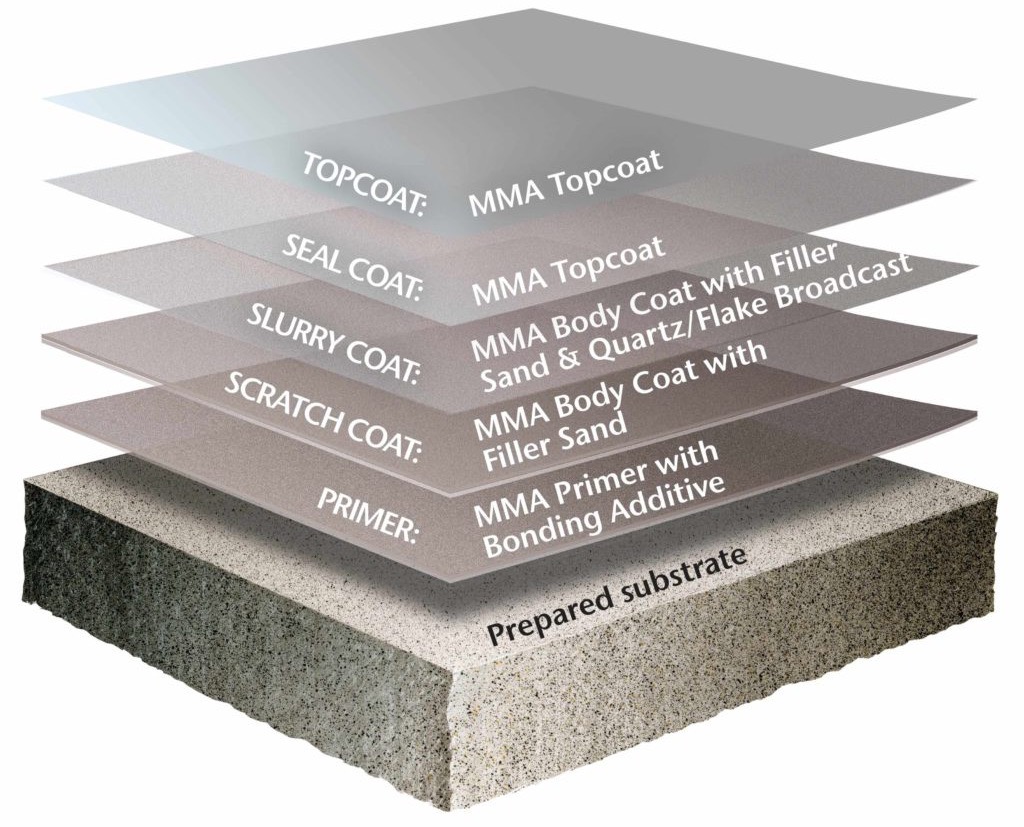

MMA, or Methyl Methacrylate, is a type of acrylic resin flooring system known for its quick-setting properties and high performance. Unlike traditional epoxy or polyurethane systems, MMA is a 100% reactive resin that cures through a polymerization process, often without solvents for a low-odour finish. It’s typically applied in layers: a primer for adhesion, a body coat for build-up, and a topcoat for protection and aesthetics.

From our work in NSW, we’ve seen MMA excel in scenarios requiring speed—curing fully in just 1-2 hours, even at sub-zero temperatures down to -40°C. This makes it ideal for time-sensitive projects where businesses can’t afford extended shutdowns. Industry experts note its seamless, non-porous finish that resists water, chemicals, and impacts, providing a waterproof barrier that’s easy to clean.

Key Benefits of MMA Flooring for NSW Applications

MMA flooring stands out for several reasons, particularly in Sydney’s variable climate and industrial demands:

- Rapid Curing and Installation: Cures in 60-120 minutes, allowing same-day return to service—perfect for overnight renovations in busy NSW factories or coolrooms.

- Temperature Resistance: Handles extremes from -40°C to +120°C, making it suitable for freezers, hot kitchens, or outdoor ramps without cracking.

- Durability and Chemical Resistance: Highly resistant to acids, alkalis, oils, and solvents; withstands heavy traffic and impacts better than many epoxies.

- Versatility: Available in self-leveling formulations, with options for slip-resistant textures, colors, and decorative flakes to match your facility’s needs.

- Low Maintenance: Its smooth surface prevents dirt buildup, requiring only neutral cleaners for upkeep, reducing long-term costs in high-traffic areas.

However, MMA does have a strong odour during application (often compared to a nail salon), so proper ventilation is essential—something we always manage in our installations.

Common Applications of MMA Flooring in NSW

In our experience serving Sydney, Central Coast, and regional NSW, MMA is frequently used where speed and strength are paramount:

- Food and Beverage Industries: For breweries or dairies, where it provides strength in high-risk spill areas and withstands daily wash-downs (as mentioned on our Brewery Floors page).

- Pharmaceutical and Cleanrooms: Low-odour variants ensure hygiene and quick installs without contaminating sensitive environments.

- Coolrooms and Freezers: Installs and cures in freezing conditions, preventing downtime in produce storage or logistics hubs.

- Warehouses and Manufacturing: Ideal for ramps, battery rooms, or chemical plants due to its UV stability and impact resistance.

- Commercial Kitchens and Bakeries: Resists hot oils and steam, with anti-slip options for safety.

MMA vs. Other Flooring Systems: Is It Right for You?

Compared to our popular polyurethane cement (DiamondCrete), MMA cures much faster, making it ideal for urgent or time-sensitive projects, though it typically has a shorter lifespan (8–15 years versus 15–25 years). While MMA shares strong adhesion with epoxy and excellent chemical resistance with polyurethane cement, its standout feature is speed—curing in just 1–2 hours compared to epoxy’s 24–72 hours—perfect for emergency repairs or minimising downtime. However, for maximum thermal shock resistance in demanding environments like food processing, polyurethane cement often performs better. Costs for MMA flooring in NSW are generally higher due to premium materials, but the significant savings in downtime often make it a worthwhile investment. Like any product, MMA has its advantages and disadvantages, so talk to us, we’re here to help narrow down the best choice for your specific needs.

| Resin Type | Cure Time | Temp Range | Typical Lifespan (industrial) | Best For |

|---|---|---|---|---|

| MMA | 1–2 hours | –40 °C to +120 °C | 8–15 years | Fast jobs, freezers, hot wash-downs |

| Polyurethane Cement | 6–12 hours | –30 °C to +130 °C | 15–25 years | Heavy-duty food plants, breweries |

| Epoxy | 24–72 hours | 0 °C to +80 °C | 5–12 years | Warehouses, showrooms |

If you’re unsure, our team can assess your site and help ensure you choose the best fit for your requirements.

FAQ,s

What exactly is MMA floor covering and how does it differ from epoxy?

MMA (Methyl Methacrylate) floor covering is a rapid-curing acrylic resin system with layers of primer, body coat, and topcoat, known for setting in 1-2 hours even in cold temperatures. Unlike epoxy, which takes longer to cure, MMA offers better UV and thermal resistance, making it ideal for demanding NSW environments. For a deeper comparison, visit our Epoxy Flooring page.

What are the key advantages of using MMA floor covering in industrial settings?

Key advantages include fast installation to minimise downtime, exceptional durability against chemicals, impacts, and extreme temperatures, hygienic seamless surfaces for easy cleaning, and customisable options for slip resistance. It’s cost-effective long-term for high-traffic areas in Sydney warehouses or breweries.

Where is MMA floor covering most commonly applied in NSW facilities?

How can I determine if MMA floor covering is suitable for my project in NSW?

Assess your needs for cure speed, chemical/thermal resistance, and traffic levels—MMA excels in fast-track installations with harsh conditions. Call us at 1800 587 172 for a 100% free consultation to evaluate your site in Sydney or regional NSW and compare with options like polyurethane cement.

✅ Let's Talk — DiamondGrind

100% free consultation — no commitment required.